Pizza Ovens

Featuring a distinctive parabolic shape, front flue and fire brick construction, our commercial pizza ovens maintain heat for longer with maximum efficiency reducing operating costs by over 50%

Our range

Our commercial wood & gas fired pizza ovens are manufactured in Britain using recycled materials

Pico

From £POA

Small but mighty, ideal for venues with a smaller number of covers, such as pubs & residential.

- Low carbon

- Low energy

- Multi-fuelled

- Segmented dome to allow for access via standard doorway

- Cooking surface made from recycled fire bricks 60mm thick

- Super energy efficient thermal mix forms the parabolic dome

- 100mm thick high density insulation with reflective vapour barrier for added heat retention

- Height with stand: 1760mm

- Height without stand: 760mm

- Width: 1190mm

- Depth: 1167mm

- 750mm fire brick base produces 3 x hand stretched pizzas

- Temperature range up to 500°c

- Cooking times from 90 to 120 seconds

- Rate – 60 pizzas per hour

- Gas burner

- Mild steel frame

- Pizza pans, paddles, brushes and rakes

- All ovens fit through a standard doorway

- Blackwood installation service available

Midi

From £POA

The middle ground, the Midi is made for small to medium-sized restaurants.

- Low carbon

- Low energy

- Multi-fuelled

- Segmented dome to allow for access via standard doorway

- Cooking surface made from recycled fire bricks 60mm thick

- Super energy efficient thermal mix forms the parabolic dome

- 100mm thick high density insulation with reflective vapour barrier for added heat retention

- Height with stand: 1760mm

- Height without stand: 760mm

- Width: 1414mm

- Depth: 1523mm

- 1100mm fire brick base produces 6 x hand stretched pizzas

- Temperature range up to 500°c

- Cooking times from 90 to 120 seconds

- Rate – 120 pizzas per hour

- Gas burner

- Mild steel frame

- Pizza pans, paddles, brushes and rakes

- All ovens fit through a standard doorway

- Blackwood installation service available

Grosso

From £POA

Our largest pizza oven, the Grosso offers space for medium to large restaurant cover.

- Low carbon

- Low energy

- Multi-fuelled

- Segmented dome to allow for access via standard doorway

- Cooking surface made from recycled fire bricks 60mm thick

- Super energy efficient thermal mix forms the parabolic dome

- 100mm thick high density insulation with reflective vapour barrier for added heat retention

- Height with stand 1825 mm

- Width 1730 mm

- Depth 1905 mm

- 1300mm fire brick base produces 10 x 300mm pizzas

- Temperature range up to 500°c

- Cooking times from 90 to 120 seconds

- Rate- 200 pizzas per hour

- Gas burner

- Mild steel frame

- Pizza pans, paddles, brushes and rakes

- All ovens fit through a standard doorway

- Blackwood installation service available

Sustainability

Blackwood Ovens low carbon journey

Traditional pizza oven high carbon journey

Blackwood Ovens low carbon, recycled materials manufacturing process

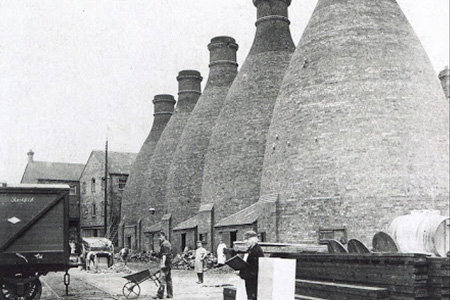

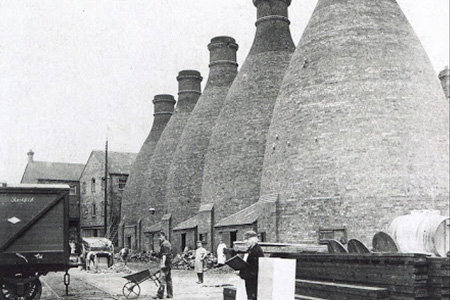

1. The bottle kilns of

Stoke-On-Trent

The bottle kilns of Stoke-On-Trent were the home of Wedgewood, Doulton and many others in the British ceramic industry.

Experts calculate that in the heyday of the pottery industry in Stoke-on-Trent there were up to 4,000 bottle kilns with as many as 2,000 still standing in the 1950's.

2. Produce high thermal

capacity recycled material

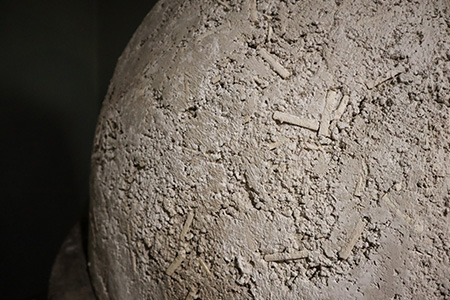

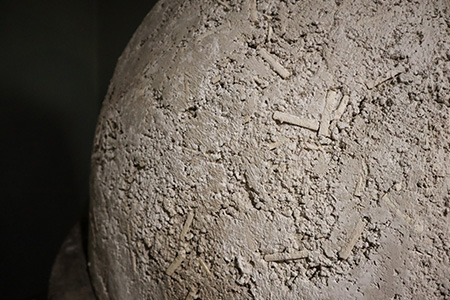

The bottle kilns would reach temperatures of 1250 degrees Celsius. The pottery is laid on refractory shelving (kiln furniture), which is fixed in place by the Ceramic firing pins. Most kiln furniture can withstand only 2 firings (bakes) before requiring replacement and it is this kiln furniture and firing pins that create our super thermal material.

3. Create parabolic

shaped mould

60mm recycled fire bricks make up the cooking base 100mm high density ceramic insulation is wrapped all around the oven dome to maximise heat retention and reduce energy consumption

The Recycling Process

Waste Bottle kiln refractory material is taken from the pottery industry which is then ground down to form a coarse sand-like consistency.

Perlite, high alumina cement and waste ceramic firing pins are then added to form a super-strong, super energy efficient, thermal mix.

This super energy-efficient thermal mix is then poured into parabolic moulds to form our dome shape oven and the base is created with this same material. Recycled fire bricks form the baking oven floor.

Recycled Materials

Our pizza oven is made up of recycled bottle kiln furniture baked at over 1400c. Waste ceramic firing pins are added for strength and act as thermal conductors to increase the thermal mass. The cooking surface is made from recycled firebricks.

- Floor – 100mm recycled refractory stone

- Cooking surface - 60mm recycled fire bricks base

- Walls – 100 mm recycled bottle kiln material

- Insulation – Double high-density insulation with reflective vapour barrier

- Additional Base Insulation – Ceramic fibre board

Manufactured in the UK using

less carbon footprint

huge saving on Co2

emmissions

Built using over

recycled materials

"One of the best ovens I have used, it’s super insulated with little heat transfer"

– Giovanni, The Dough Ball Pizza Co

A UK manufactured range of commercial smokers, pizza ovens & hot holding cabinets